Aluminum extrusion linear rails are 3D distributed linear rails that offer precise control and stability during high-speed motion applications. They are designed to significantly improve the performance of your machines, as they are built to offer far greater accuracy and stability than their traditional round rod counterparts. But how do they achieve these benefits? And what makes them so unique?

One of the primary advantages of aluminum extrusion linear rails is their resistance to deflection. Deflection is when a linear rail bends or warps under the weight or pressure of a machine or tool, which can lead to inaccurate and unstable positioning. By using high-grade aluminum extrusions, these linear rails can withstand high levels of stress without bending or warping, maintaining their form and ensuring accurate and stable tool positioning.

Another advantage of aluminum extrusion linear rails is their smoother motion. This is due to their improved mounting system, which eliminates the need for additional hardware or complicated mounting procedures. The aluminum extrusion system simply requires an easy-to-install mounting bracket for a smooth and easy setup. The system also offers better clearance, reducing any risk of collisions between the bearing and motion elements, further improving its smoothness.

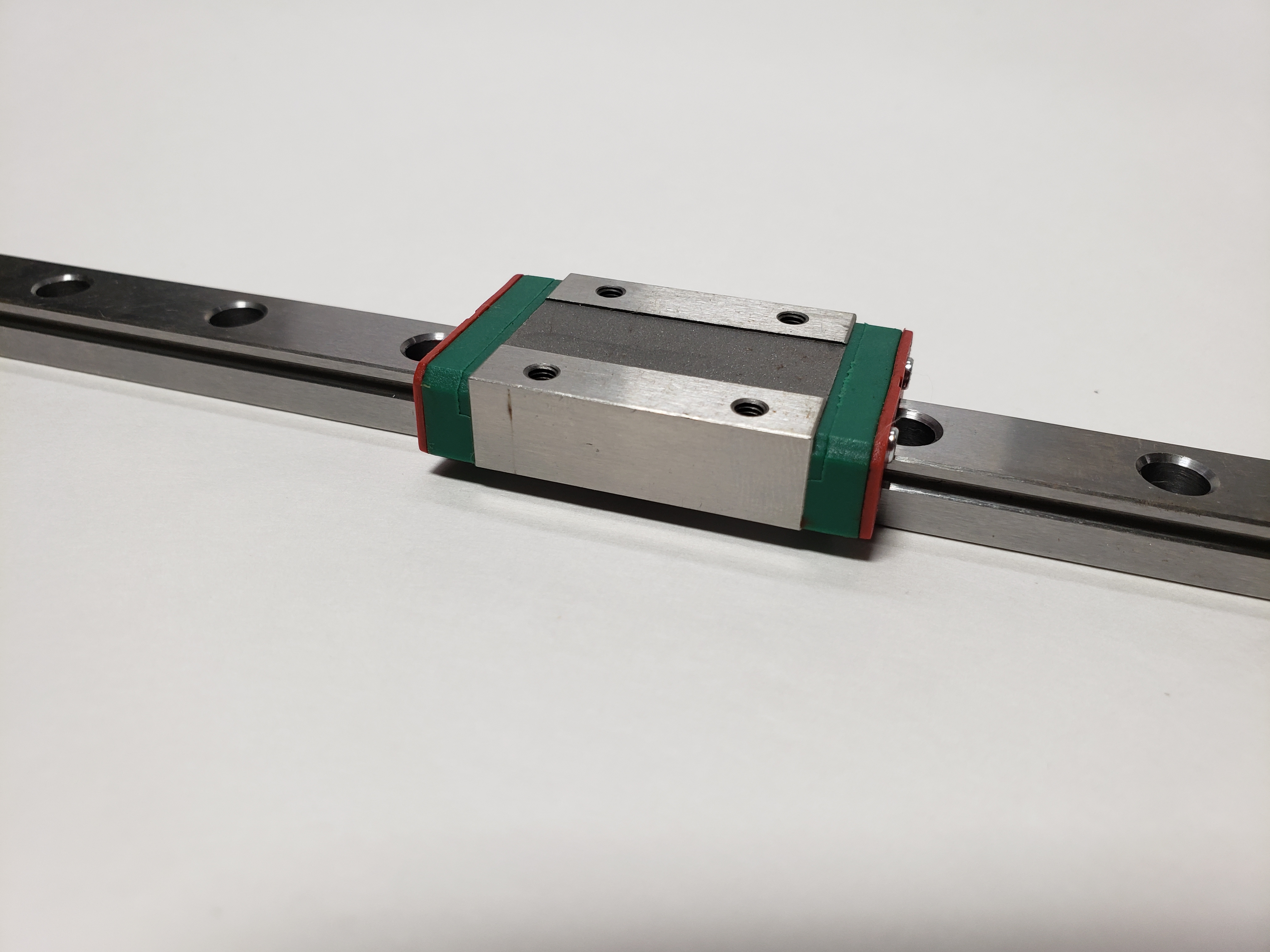

The mounting system of aluminum extrusion linear rails isn't the only feature that contributes to their smoother motion. These rails also have a more refined and precise bearing system that ensures stability during high-speed motion applications. The bearing system consists of a durable and low-friction polymer material, combined with an optimized design that allows for precise clearance between the bearing and rail. The use of this high-quality material results in a more stable ride and a cleaner, smoother motion.

The aluminum extrusion linear rails also offer stability during high acceleration and deceleration motions. They have a higher load capacity than their traditional round rod counterparts, which means they can handle heavier loads while maintaining their precision and alignment. This feature is particularly important in heavy manufacturing environments, where machines can be subjected to high-speed motions and heavy loads.

In conclusion, aluminum extrusion linear rails are a technological breakthrough that provides superior performance compared to traditional round rod linear rails. They offer better accuracy, stability, smoother motion, and a high load capacity, making them ideal for high-speed motion applications. The benefits of aluminum extrusion linear rails make them an ideal choice for any industrial or manufacturing environment.